You give your embroidery machine a clean design with fresh fabric. The first few stitches look perfect. Then suddenly snap and the needle breaks. This is a sad moment because needle breakage wastes time, damages fabric, and disturbs your workflow. 70% embroiderers face this problem, even after years of experience. Needle breakage happens for a reason. When you understand the causes and fix them step by step, your machine runs smoothly and your designs stitch cleanly.

This guide explains everything so you can stop needle breakage before it starts

Needle breakage usually happens due to machine setup issues, fabric resistance, or incorrect needle use. When one small setting goes wrong, the needle takes the pressure and breaks.

Thick fabrics like denim and leather type put strong pressure on the needle. When the needle can't enter the material smoothly, it bends and breaks.

So in short

- Thick fabric resists needle penetration.

- Multiple fabric layers increase needle pressure.

- Hard surfaces slow down needle movement.

- Stiff materials bend the needle on impact.

- Dense areas cause repeated needle stress.

Tightly woven or layered fabric increases resistance. If the design density stays high, the needle hits heavy stitch areas again and again, which causes stress.

- Tight weave blocks smooth needle entry.

- Overlapping stitches increase friction.

- Dense patterns stuck the needle in one area.

- Poor fabric quality causes uneven resistance.

- Mixed fabric layers react differently to stitches.

Each fabric needs a specific needle type. A thin needle on thick fabric or a sharp needle on unstable fabric increases breakage risk.

- Thin needles snap under heavy pressure.

- Sharp needles damage delicate fabrics.

- Ballpoint needles fail on firm materials.

- Wrong needle length affects hook timing.

- Weak needle coating increases friction.

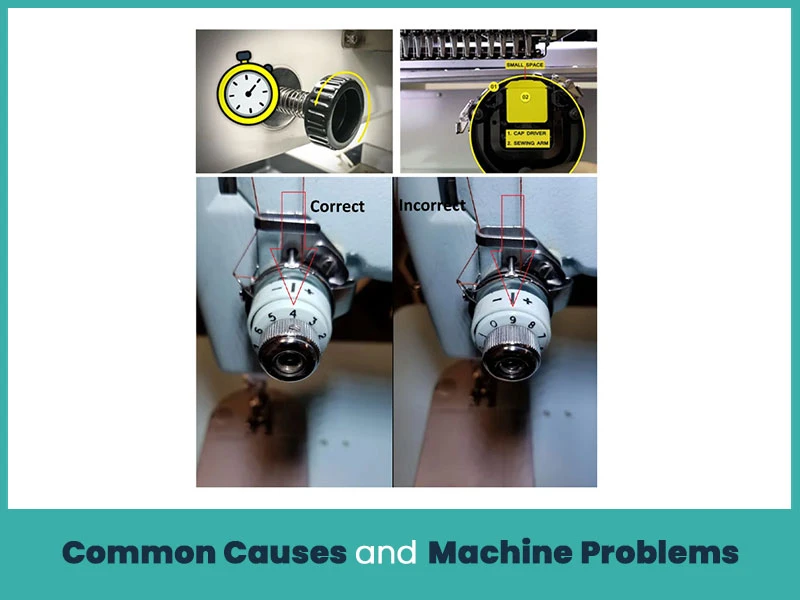

When the cap driver sits too high, the needle strikes metal parts during stitching. This impact leads to instant needle damage.

- Needle hits the cap frame during stitching.

- Poor height setting causes metal contact.

- Needle angle changes during rotation.

- Cap movement increases needle stress.

- Incorrect driver position affects stitch balance.

Incorrect machine timing causes the hook and needle to miss alignment. Flagging pulls fabric up with the needle, which bends it during every stitch.

- Needle misses hook alignment.

- Fabric lifts with needle movement.

- Loose fabric bends the needle upward.

- Flagging increases stitch resistance.

- Timing issues create uneven stitch loops.

Wrong threading, tight thread paths, or rough thread tension create drag. This drag pulls the needle off its natural movement path.

- Incorrect thread path adds drag.

- Tight tension pulls needle sideways.

- Rough thread damages needle surface.

- Improper bobbin placement causes imbalance.

- Thread knots increase needle pressure.

You can easily stop needle from breaking with the right setup, using correct essentials, and maintaining your machine on a regular basis because small steps make a big difference.

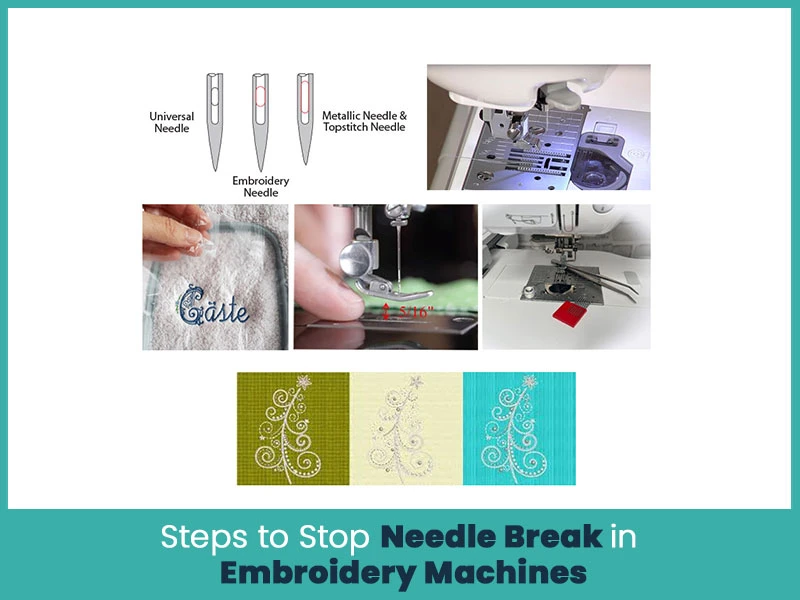

Always match the needle size to fabric's nature. Use larger needles for heavy fabrics and smaller needles for light materials. This balance reduces stress on the needle.

Dull or bent needles weaken over time. Replace needles after several designs or whenever you notice skipped stitches or fabric damage.

Hoop fabric firmly and use the right stabilizer. Loose fabric moves with the needle and causes bending during stitching.

Slow stitching gives the needle time to enter dense areas. High speed on tough fabric increases pressure and breakage.

Set the presser foot close to the fabric without pressing too hard. Proper height prevents fabric lift and needle deflection.

Correct timing keeps the hook and needle in perfect sync. Regular checks help prevent metal contact and missed stitches.

Dense stitch designs damage light fabric. Reduce stitch count or adjust density for smooth needle movement.

Low-quality thread creates friction and uneven tension. Balanced thread flow keeps the needle stable during embroidery.

Needle breakage during stitching is so annoying because it always creates a mess. Fabric choice, needle size, machine speed, and design density even everything can cause issues. When you focus on these factors, then your embroidery machine works perfectly and stitches clean designs without any interruption. Careful setup & regular maintenance will protect your needles and improve embroidery quality.

If needle breakage continues due to design issues or poor digitizing, professional help makes a real difference. True Digitizing creates clean, balanced embroidery files that reduce stress on needles and machines. Get your designs digitized by experts who understand stitch flow and fabric behavior. Place an order today and get stitch designs with confidence.

Nick William has been immersed in the world of embroidery digitizing for over 20 years, earning 25 industry awards throughout his career. As a 3rd generation embroidery expert, Nick’s journey started in his family’s workshop, where he learned the art of digitizing before the rise of modern software. He has worked with leading commercial embroidery businesses and has shared his expertise with over 75,000 home and professional embroiderers. As an author at True Digitizing, Nick is passionate about teaching others how to create beautiful, precise designs through easy-to-follow tutorials and expert advice.

Categories

How to Do Machine Embroidery on Sleeves Like a Pro

04-02-2026

Embroidery Stitches Explained | How to Choose the Right Stitch Type for Your Design

27-01-2026

Which is the Best Embroidery Machine Brand in 2026 (Home & Commercial Use)

22-01-2026

Romantic Shirt and Hoodie Embroidery Ideas for Couples in 2026

20-01-2026

How to Reduce and Prevent Machine Embroidery Puckering

17-01-2026

Common Client Errors When Submitting Logos for Embroidery

17-01-2026

Top 5 Best Brother Embroidery Machines For Beginners

09-01-2026

New Year Trends in Custom Embroidery for Apparel Brands 2026

05-01-2026

Manual vs Auto Digitizing for Logos | Why Professionals Prefer Manual

19-12-2025

Winter Themed Embroidery | Snowflakes, Trees, and Cozy Designs

17-12-2025