You are ready to set your embroidery machine, load the design and start stitching. Everything looks fine until you turn the hoop over and see a bunch of thread tangled under the fabric. Ah! It feels so annoying. You notice loops, knots and messy thread that ruin your design, fabric and waste your time but don’t worry guys, this happens to many embroiderers. The good thing is, this common problem can be fixed easily.

In this informative post we’ll look at what thread nesting under fabric means, dig into why it happens and walk you through how to fix it and prevent it from happening again.

“Thread nesting,” also called “bird’s‐nesting,” refers to when the thread bunches up underneath your fabric between the hoop and the needle plate instead of forming tidy interlocking stitches through the fabric.

Well the top of your design may look fine but the thread loops underneath can jam the bobbin hook or distort the fabric, causing machine stops, skipped stitches or ruined garments.

Here’s what the trouble looks like: you pull off the hoop and you see a small mound or loops of thread on the underside. The upper thread didn’t pull tight and settle properly so it looped under the fabric rather than forming the lock stitch at the correct layer. As one source puts it: “bird nesting is the accumulation of thread caught between an embroidered piece and the needle plate.”

The causes range from threading mistakes, tension issues, bobbin problems, hooping errors to poor maintenance.

By understanding exactly what’s going wrong, you can fix the issue and avoid it on future projects.

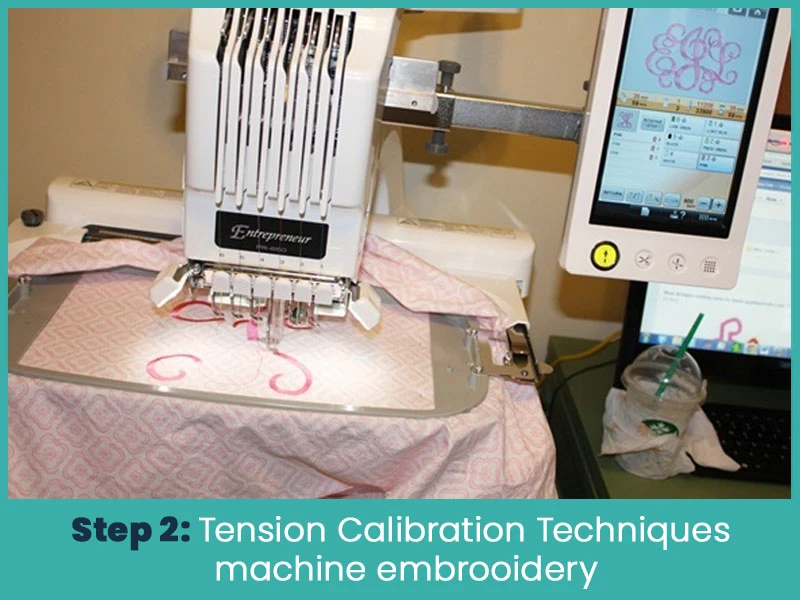

Here are 4 major areas to focus on when you’re dealing with thread nesting. Think of this as your go-to checklist.

When nesting happens, the first thing to do is stop the machine and re‐thread both the upper and lower thread paths. It sounds simple but many problems start with a skipped guide or tension discs that didn’t fully engage.

Raise the presser foot (this lifts open the tension discs so the thread can sit correctly).

Remove the upper thread entirely and re‐thread from the spool, through each guide, tension discs, take-up lever and needle.

Then remove the bobbin and check it.

Thread the bobbin correctly, insert it in its case and replace the case, making sure it’s seated properly.

Proper threading makes sure the thread moves smoothly through the machine and gets the right amount of tension. Improper threading is a leading cause of bird nesting.

Many nesting issues trace back to tension imbalance, usually the upper thread being too loose, or bobbin tension not being correct. Over 80% of under-fabric thread bunching is caused by loose upper thread tension.

Here’s how to check and adjust tension:

With the machine stopped, look at a test stitch: If loops are visible on the underside, loosen the upper tension slightly or tighten the bobbin tension depending on your machine model.

If the top thread shows through the underside, then upper tension may be too tight.

Always test on a scrap of the same fabric and stabilizer you’ll use for the real piece.

You want stitches that appear even on the top and the bottom, no visible loops or thread tails.

Keeping the right thread tension needs both some understanding and careful attention. The goal is a clean interlock inside the fabric, not above or below it.

The bobbin area is often overlooked but it’s a key player. If the bobbin is put in the wrong way or threaded unevenly, the wrong type or the case is dirty, nesting can happen.

Steps to check:

Remove the bobbin case and inspect for lint, broken bits or burrs on the plate.

Check the bobbin position. Some machines require the bobbin to turn in a specific direction; if it’s reversed, thread movement may be blocked.

Check the bobbin tension (some machines allow micro‐adjustments).

Replace the bobbin case or plate if it’s nicked or damaged.

Use correct bobbin size and thread type recommended by your machine manufacturer.

If your bobbin area is clean and set correctly, a majority of nesting issues will be resolved.

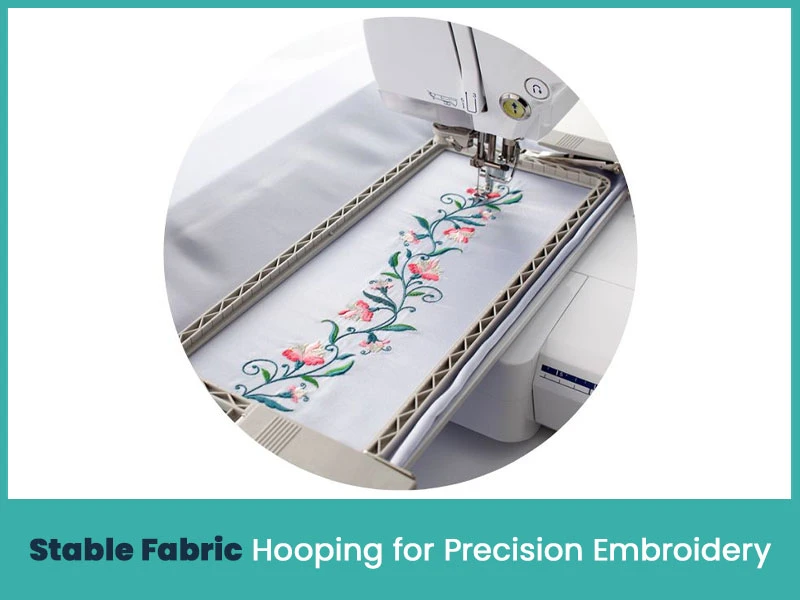

Even if your machine is perfect, a poor fabric setup can undo your best efforts. If fabric moves or shifts in the hoop, thread can loop underneath instead of locking in properly.

Here are tips for fabric setting:

Use a good quality stabilizer (both under and optionally on top) depending on your fabric type.

Make sure the fabric is hooped tightly, it should feel like a drum when tapped. Loose fabric helps movement during stitching and can lead to thread bunching.

For thick or uneven fabrics, use proper hooping techniques: multiple layers of stabilizer, correct hoop size and check fabric tension before you begin stitching.

Make sure the hoop is level, the fabric is flat and you haven’t distorted the fabric in the hoop. Any flagging, fabric bouncing or lifting can cause problems.

By aligning machine threading, tension, bobbin setup and fabric hooped properly, you significantly reduce the risk of thread nesting.

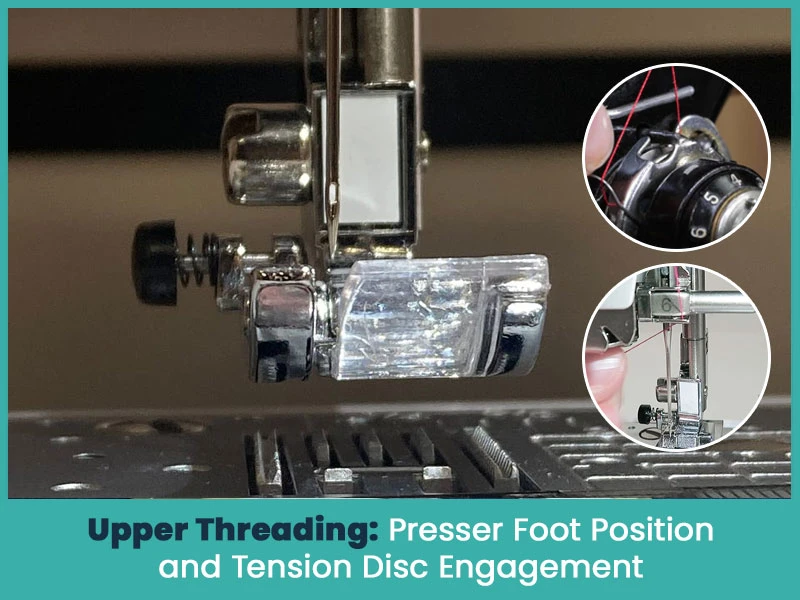

Proper threading is very important. Let’s break it down further into two key sections: upper threading and bobbin threading.

Threading the upper path correctly is more than just following the arrows. It means making sure the presser foot is up when you thread so the tension discs are open. Then, after threading, you lower the presser foot so the discs can clamp the thread properly. If you skip that, the thread may slip and cause loops underneath.

Key points:

Follow the machine manual’s threading path carefully.

After inserting the thread into the needle, gently pull the thread tail so you can see the take‐up lever move up and down.

Make sure the thread passes firmly through the tension discs, guides and take-up lever.

Use quality thread (cheap or old thread frays and adds lint, increasing risk).

The bobbin side is equally important. Here’s what to see :

The bobbin must be threaded evenly and inserted in the correct direction. A reversed bobbin is a common cause of nesting.

The bobbin case and surrounding area must be clean and free of lint. Debris interferes with smooth thread flow.

The bobbin tension spring (for machines that have one) should not be too loose or too tight. If the bobbin thread pulls too freely or won’t pull at all, the stitches won’t lock properly.

After threading, test with scrap fabric before you begin your project. Check both sides of the fabric to confirm a clean stitch.

By paying careful attention to both upper and bobbin threading, you form a solid base for nest-free stitching.

Hooping often gets treated as an afterthought but we’ll emphasise it here because it plays a major role in preventing thread nesting. If your fabric moves while stitching, the thread tension and lock position can shift mid‐stitch, causing loops underneath.

Here are practical tips:

Choose the right size hoop for your design. It should help minimize fabric slack.

Pre‐press your fabric if needed so it lies flat and stable.

Use the right stabilizer under the fabric and consider topping it (if appropriate) to keep fabric from pulling through the stitches.

Check for “flagging” when the fabric lifts during stitching. If you notice movement, stop and re-hoop.

Make sure the hoop is clean, the screw or clamp is tight and fabric stays properly (not twisted or stretched).

When fabric is hoop-secure and stable, the rest of the machine setup (threading, tension, bobbin) can do its projects properly and stitching remains consistent without nasty surprises underneath.

Thread nesting under fabric is so frustrating, it doesn't have to cause your project to fail. By methodically checking your threading, calibrating your tension, inspecting your bobbin system and securing your fabric with proper hooping, you can turn a recurring problem into a rare inconvenience.

Nick William has been immersed in the world of embroidery digitizing for over 20 years, earning 25 industry awards throughout his career. As a 3rd generation embroidery expert, Nick’s journey started in his family’s workshop, where he learned the art of digitizing before the rise of modern software. He has worked with leading commercial embroidery businesses and has shared his expertise with over 75,000 home and professional embroiderers. As an author at True Digitizing, Nick is passionate about teaching others how to create beautiful, precise designs through easy-to-follow tutorials and expert advice.

Categories

How to Reduce and Prevent Machine Embroidery Puckering

17-01-2026

Common Client Errors When Submitting Logos for Embroidery

17-01-2026

Top 5 Best Brother Embroidery Machines For Beginners

09-01-2026

New Year Trends in Custom Embroidery for Apparel Brands 2026

05-01-2026

Manual vs Auto Digitizing for Logos | Why Professionals Prefer Manual

19-12-2025

Winter Themed Embroidery | Snowflakes, Trees, and Cozy Designs

17-12-2025

Top 25 Christmas Machine Embroidery Designs for Holiday Gifts 2025

12-12-2025

Best Multi-Needle Embroidery Machine Comparison | Brother, Tajima, Janome, Barudan & More

09-12-2025

Step-by-Step Guide to Convert SVG Files into Embroidery Designs

04-12-2025

Mastering Pull and Push Compensation in Embroidery Digitizing: A Complete Guide

02-12-2025